There are manifold types of different things that decide if a new flange connection is going to be secure and leak-free. One of the most crucial is the bolt tightening sequence. Even if you are using a perfect bolt tightening machine, make sure that the sequence is the right. You cannot take a chance with anything.

To a new bolting person, this could seem candid enough. But just applying full torque to your first bolt and next moving onto the head-to-head one is the incorrect approach. The order in which you actually tighten the bolts and the load applied has a massive impact on the honesty of the joint.

Actually, you know what, to finish a flange joint safely, it is crucial to control the stress variation in the proper flange joint components. In the instance of the gasket, this requires to be evenly compressed throughout the flange face. In case you were to tighten head-to-head bolts when those opposite remain loose the outcomes could be uneven compression and even that of possible damage to the gasket.

The flanges should be brought together gradually and be parallel. In practice, this simply means starting by making use of the correct bolt tightening pattern at partial load, and then performing various more bolt passes, enhancing the load every single time. even if you are using tightening torque for bolts calculation, make sure that you do not lose the sight of the proper sequence.

What to know about Bolt Tightening Patterns?

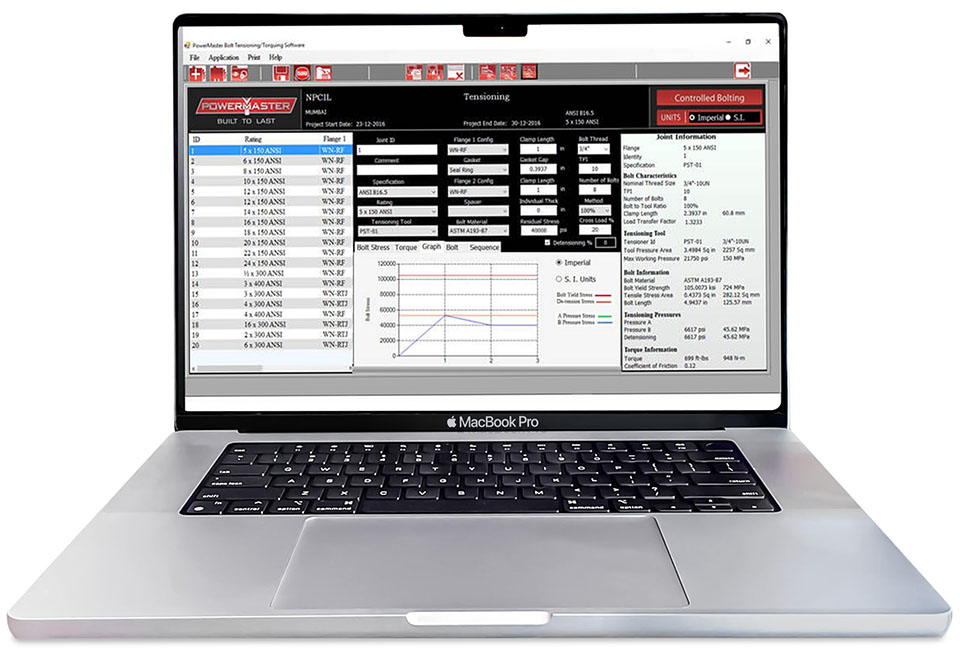

The mostly standard is the ‘go-to’ document for simply bolting standards. it is simply about giving manifold options for tightening sequences which if followed rightly are going to help to ensure a leak free type of flange joint.

Before you tighten them, bolts can be properly numbered sequentially like one, two, three four, five and so on in a clockwise direction across the flange (fig 1 below). Or they can even be numbered by the order of tightening (fig two below). Remember that both these methods have their perks, but it is crucial that the one chosen is agreed in pre-job briefs and even that the tightening crews are appropriately trained.

Actually, to a newbie or a novice, this all might seem more complicated and overwhelming. But by following the right type of procedures and taking the additional time will help evade possibly risky and time-consuming maintenance in the near future. The point is once you use the right -designed hydraulic torque wrench will make the procedure efficient and absolutely trouble free. These are available from as square drive hydraulic torque wrenches and even that of low-profile hydraulic torque wrenches.

Conclusion

0 comments:

Post a Comment